hardness test location|hardness testing process : wholesalers Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 .

webCibelly Bar em Cabedelo - menu, ⏰ horário de funcionamento, ☎️ número de telefone, 📍 endereço e mapa.

{plog:ftitle_list}

WEBPrevisão Numérica de Tempo. São Paulo / SP | Outro Local: Por Período. Próximos dias. Previsão Estendida. Meteograma. Quinta-Feira. 29/02/2024. Manhã 5% Tarde 67% .

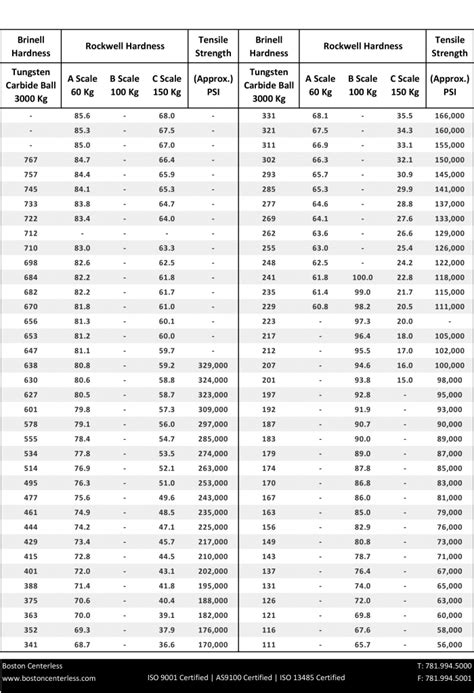

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). The most commonly used low-load method is Vickers.The principle of electronically controlled and permanently monitored load application .In hardness testing according to Rockwell, the total test force is applied in two .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

This article will discuss hardness testing, its definition, how it works, its types, and benefits. An Overview of Hardness Testing and How it Works. Hardness testing measures a material’s resistance to permanent .

Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 .

Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined .

TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .Element offers one of the most extensive ranges of hardness testing available – covering micro/macro hardness testing, in lab and field options plus all the choice techniques (Rockwell, Brinell, Bickers) alongside less common specialized . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.

The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .Each hardness test method, or scale, is defined with a particular type of indenter, a specified . Pay attention, to the location of the sample 3Dtable and cameras. Use the vertical positioning knob to lower the table from the cameras before using the button selector. The button selector is aTableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 .

The Brinell hardness HBW results from the quotient of the applied test force F (in newtons N) and the surface area of the residual indentation on the specimen (the projection of the indentation) after removal of the test force (see Brinell formula).To calculate the surface area of the residual ball indentation, the arithmetic mean d of the two perpendicular diagonals d1 and d2 (in mm) is .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .

Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for the Mohs scale do not have a graded increase, the Mohs scale lacks accuracy and is only a rough measure of hardness. .

transverse section through the threaded component. Hardness testing can be carried out using Vickers, Brinell or Rockwell hardness testing as per ASTM/ISO standards. Cross-sectional hardness evalution For transverse section of the threaded component, hardness testing should be carried out as illustrated in Figure 2 within the half radius area.

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness Testing Considerations The following sample characteristics should be considered prior to selecting the hardness testing method to use: • Sample Size • Cylindrical Samples • Sample ThicknessDownload scientific diagram | Sample of welding joint with locations of hardness and microstructure testing Results and Discussion The result of vickers hardness testing is shown at figure 3, The .

piston scuff test

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional examinations in the sequence. . A modest load is applied to the surface first to establish the zero location. Once the zero .

Test location Material homogeneity . For the lowest hardness test force, the 15 Kgf scales, a polished or lapped surface is recommended. Care should be taken when finishing any material prior to testing to avoid the possibility of causing a .MicroDur Hardness Testing: Determination of hardness of metallic materials by the Ultrasonic Contact Impedance (UCI) method, as specified in ASTM A1038, is done using the MicroDur series of hardness testers. The UCI method uses a Vickers diamond indenter, allowing for precise placement of the indent and resulting in a highly localized hardness .Download scientific diagram | Hardness test locations on the specimen from publication: Influence of thermal ageing on long term reliability of SnAgCu solder joints | Reliability of SnAgCu solder .4.3 Rockwell hardness testing at a specific location on a part may not represent the physical characteristics of the whole part or end product. . Rockwell hardness test, the preliminary test force is 10 kgf (98 N) and the total test forces are 60 kgf (589 N), 100 kgf (981 N),

Some limitation for hardness test as follows :- Type of material Specimen thickness Test location Scale limitations 1. The Brinell hardness test J.A. Brinell introduced the first standardized indentation-hardness test in 1900. The Brinell hardness test consists in indenting the metal surfaceLeeb Hardness Test. The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically. Used for materials with a coarse or inhomogeneous grain .

Hardness testing by TÜV Rheinland: Ensure the quality of metal with our service for hardness measurement, including Rockwell, Brinell, and Vickers tests. . locations. press and media. World Site / EN. Choose country/ region and language. World Site. EN Albania. EN Algeria. EN Algeria. AR Algeria. FR Argentina. ES Armenia. EN Australia. EN

standards for hardness testing

A full selection of hardness testers, testing machines, testing equipment and accessories for Vickers, Knoop, Brinell and Rockwell hardness testing from Struers, the world’s leading materialographic and metallographic equipment supplier.The definition of the hardness testing location is outside the scope of the standard, but hardness requirements must be met regardless of the chosen test location.This question is in relation to NACE MR0175/ISO 15156-3 Table A.2Reference: ISO 15156 Maintenance Panel Inquiry #2006-05At OGC Energy help clients meet NACE MR0175 requirements .Mohs Hardness Test: This qualitative test ranks minerals based on their scratch resistance against standard materials with known hardness values. It’s commonly used in geology and mineralogy for mineral identification. These hardness testing methods serve various purposes, from quality control in manufacturing processes to material selection .

astm standard for scuff test

4.3 Brinell hardness testing at a specific location on a part may not represent the physical characteristics of the whole part or end product. Scope. 1.1 This test method covers the determination of the Brinell hardness of metallic materials by the Brinell indentation hardness principle. This standard provides the requirements for a Brinell .

We provide a tool on our website to search your zip code's average water hardness here. You can also purchase art home testing kits to check your water hardness. We recommend reagent tests like Hach 5B Total Hardness Test Kit. You can also contact a water technician in your area to test your water.Brinell hardness test. The oldest common method for hardness testing is the Brinell test. It was developed by Johan August Brinell as early as 1900. The Brinell hardness test is suitable for materials with an inhomogeneous or coarse particle size distribution, and for large samples, because this test method creates a rather large impression. A .

Significance and Use 3.1 Portable hardness testers are used for testing materials that because of their size, location or other requirements such as test point are unable to be tested using traditional fixed instruments. 3.2 Portable hardness testers, by

hot scuff test

cold cuff test

scuff test standard

19 de abr. de 2021 · Superliga europeia: o que se sabe sobre a competição. Seis dos 12 clubes fundadores já desistiram, e torneio é suspenso 48 horas após o anúncio. Confira .

hardness test location|hardness testing process